DiSlip

| Nano hardness | 30-50 GPa |

|---|---|

| Coating thickness | 1 µm |

| Coefficient of friction | 0.15 |

| Max. service temperature | 450 °C |

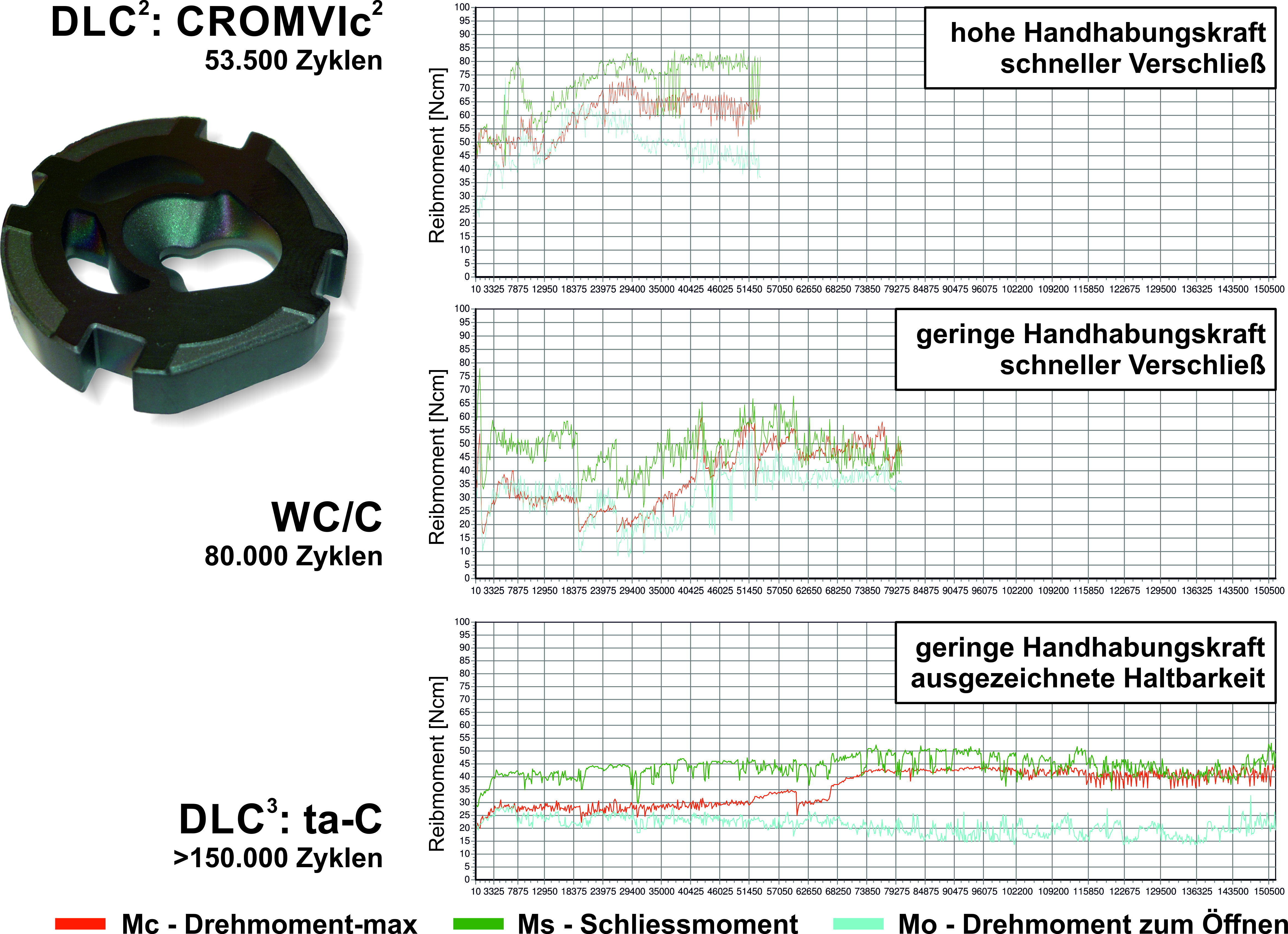

ta: C - The hard DLC layer for components and micro tools

DLC1 and DLC2 layers with hydrogen are based on metals, nitrides, water and carbon. The carbon (mostly from acetylene) is deposited as a top layer as a lubrication layer [4].

One can speak of hard DLC layers, of ta:C coatings over a 50% proportion of sp3 crystals. It means a hardness above 50 GPa and a roughness smaller than Sa = 50 nm.

The thin (~ 1um) layer is ideally suited for coating micro tools and components that are exposed to constant frictional loads on the moving components